Call now

How efficient are modern condensing boilers?

posted on 30 Sep 2021Today I am going to show you how you can save money on your central heating and hot water gas bills. Yes – we are talking about system efficiency or actually rather we are talking about why most gas boilers are notoriously inefficient. If you apply principles discussed in this blog you will not only be able to save yourself few hundred pounds a year but you will also learn how to run your system in a way that will prevent your boilers from breakdowns and costly repairs.

“What? Systems that runs efficiently prevent boilers from breaking down? What kind of voodoo is he talking about?”

Well, as you will see there is a correlation between inefficient systems and longevity of your boiler and system components – but we will get to that.

EFFICIENCY

What is efficiency? Firstly we need to distinguish between following aspect of efficiency:

– your house energy efficiency – it basically means how quickly your house is losing heat – we call it a heat loss and we calculate a specific value for each property. The lower the value measured in kWH to better the efficiency of the property

– your heat generator efficiency – this is a gas boiler in our example, but it could also be a heat pump, electric boiler or an oil boiler. The efficiency of a gas boiler is simply the difference between energy we put in in form of gas and usable heat output we receive to heat our homes. In case of gas boilers there is always some heat lost through the flue as products of combustion

HOW TO GET MORE FROM YOUR GAS BOILER

General rule of thumb when it comes to gas boiler efficiency is: the lower your boiler return pipework temperature the higher your system efficiency all other things being equal. Your gas boiler has a pipe called flow – this is where hot water enters your system on its way from the heat exchanger to the radiators or other heat emitters. That hot water losses it’s heat or energy being dissipated through radiators and then comes back cooler to the boiler through a pipe called Return to be heated again.

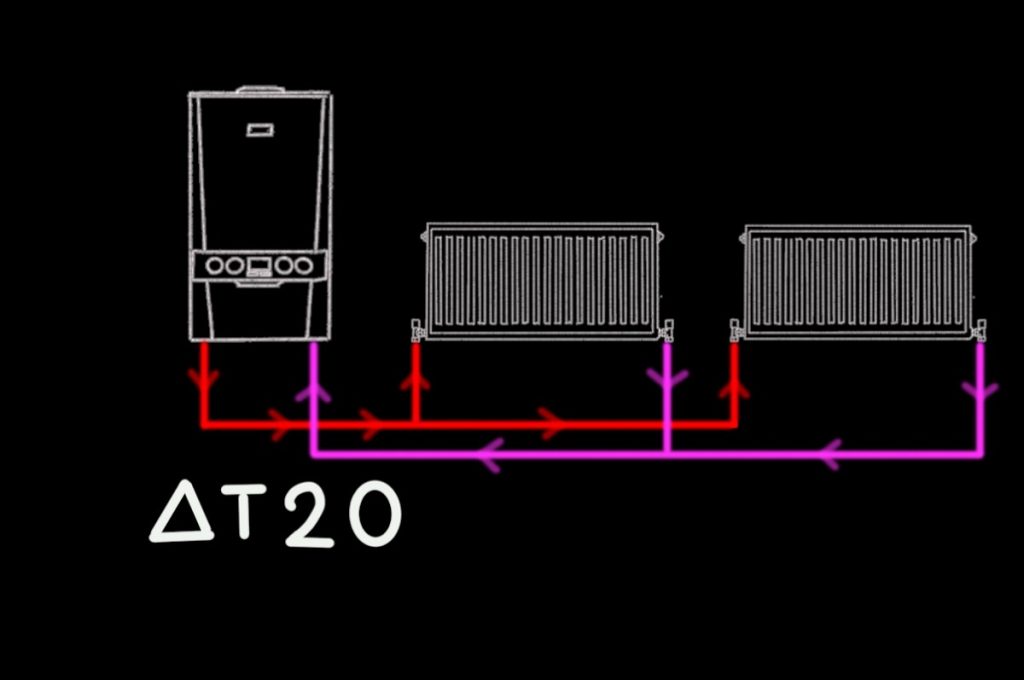

On modern condensing boilers we try to design the systems in a way that the difference between the flow and return in around 20 degrees. We call it DT 20. For example – if you take your average boiler out of the box it will be most likely set to 75 degrees flow giving a theoretical 55 degrees return.

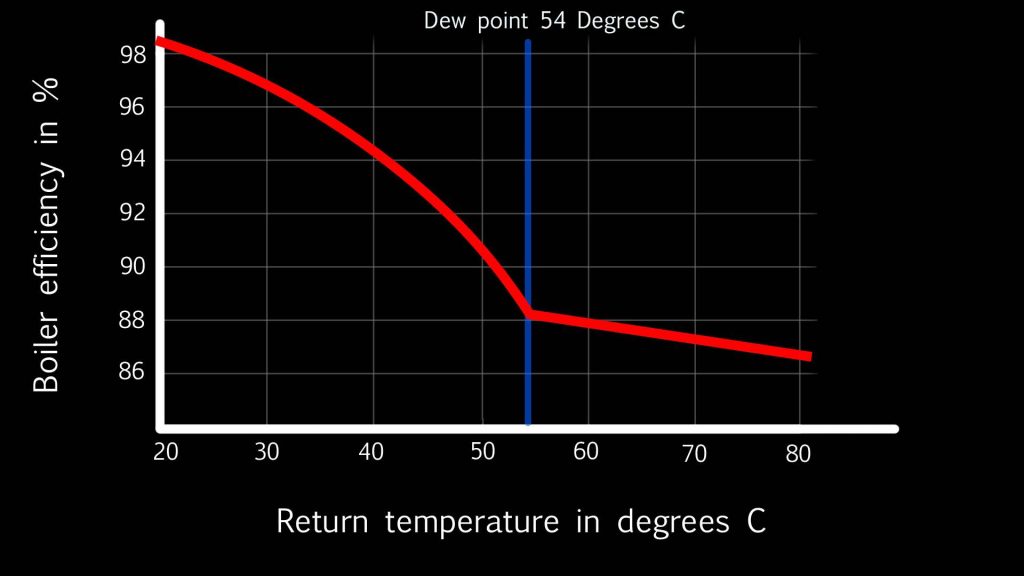

The lower we can get the return pipework temperature the higher your boiler efficiency. This graph illustrates this principle.

As you can see there is a big jump in efficiency from around 86% when the return temperature drops below 54 degrees. This is what is called a dew point or condensing mode. At around 54 degrees return we enter a condensing mode at around 88% efficiency. But if we look at the graph we can also see that there is a theoretical 97% efficiency possible. The only trouble is the return temperature would have to drop to areound 20 degrees. As you can also see on this graph there is a sudden jump in efficiency once we go below 54 degrees of boiler return. This is because products of combustion change it’s state form gas into steam. We call this change a ‘phase change’ and it releases larger amounts of energy that we call latent heat.

Latent heat: the energy required to transition one unit of a substance from solid to liquid; equivalently, the energy liberated when one unit of a substance transitions from liquid to solid.

Realistically we can run gas fired boilers at 30 degrees return pipework with 94-95% efficiency. Wet underfloor heating is one of the ways we can achieve those high efficiencies. We could also oversize radiators to be able to run the system at lower return temperatures. Hopefully by know you start to understand that it is not the make of the boiler that will make your system more efficient. The way it is set up and run in much more important.

Since now we understand modern condensing gas boiler efficiency and we know that we want to run the boiler at the lowest possible temperatures to achieve higher efficiency, what are the practical steps we can take to make sure that our gas fired central heating is super efficient?

HEAT LOSS

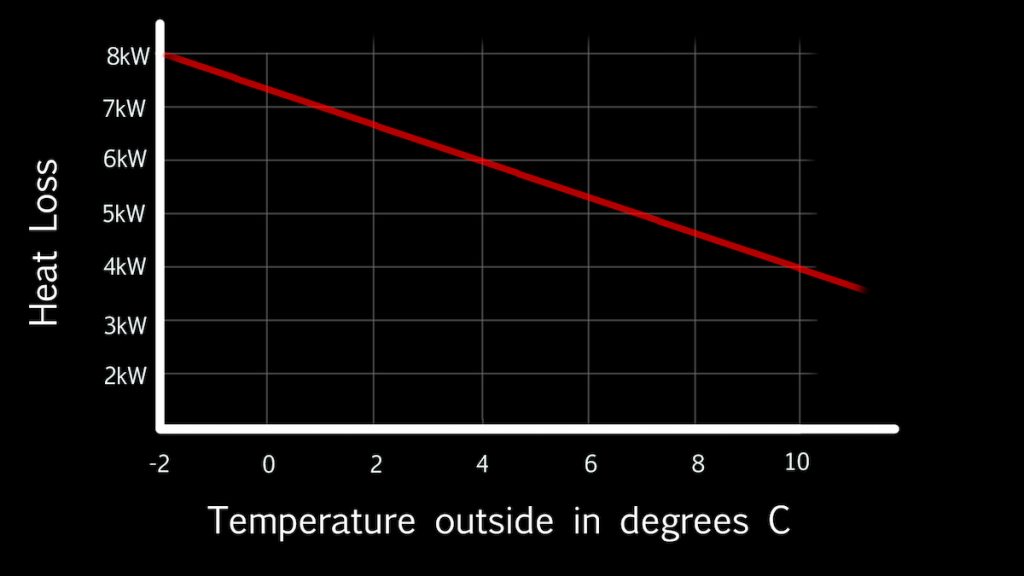

Heat loss of your home is where it all starts from. It is basically the speed at which the building looses heat. Heat loss calculations are based on many factors – but for our purposes the most important is the fact that the figure is based on a fixed external temperature, usually around -2 degrees. What we have to remember is the fact that this is assumed worst case scenario and that most of the year the external temperatures will be higher than -2. What does it mean for our central heating and our boiler? Well, it means that most of the time our radiators and the boiler will be oversized. It also means that most of the time it will be perfectly fine to run for boiler at a fraction of it’s output and also at lower temperatures giving us more efficiency and savings. To illustrate this idea I have borrowed a table from Kimbo from ‘Heating Academy in Northampton’ – Kimbo runs excellent heating and hydroponics courses for installers and I highly recommend his training to anyone in the heating industry.

This shows a relation between the heat loss calculated at -2 degrees and how it changes with the rise of external temperature. In this example we have 8Kw at -2. As you can see at 10 degrees we will only need 4kW.

PRACTICAL STEPS FOR HIGHER EFFICIENCY

1. Boiler sizing

Now we understand the relation between the boiler return temperature and boiler efficiency. We also know that the warmer the weather the lower boiler output we need.

The question is therfore: what is the most efficiecnt way we should heat our homes? Should you have a big boiler that can blast loads of heat and bring the property to nice comfort levels of temprature or maybe it is better to have a low output boiler that stays on for much longer periods simply maintaning the heat lost to the colder outside?

There is a number of problems with running your boiler flat out or with having and oversized boiler for your needs. As a matter of fact vast majority of gas boilers installed in UK are oversized. Keep in mind that the average heating requirement for a property in the UK is around 8kW. Or to put it differently 80% of UK housing stock requires less than 8kW heating.

Boilers have fixed modulation ratios. It means they can only modulate so low. There are notable exceptions of large boilers that can modulate very low but those are not very common. If you choose your boiler next time, remember – bigger is not always better. So what happens when we oversize the boiler you ask? Well, the boiler will not be able to modulate down to let’s say 4kW when it is 10 degrees outside and it will reach the set point very quickly and then it will shut down and wait to cool down. Then the process will start again, boiler will overheat and it will cycle on forever. This creates a situation when the boiler is no longer working efficiently. It also puts undue strain on the boiler components as they start and stop more often. It also puts additional stress on the heat exchanger due to thermal expansion and contraction. In the end your boiler will have much short life span and will never be as efficient as it could be if it was sized correctly. The advice here is: size your boiler correctly to the system and pay special attention to how low the boiler can modulate down. The lower the better and it will not only save you money on your heating bills, it will also keep the boiler components from falling prematurely

2. Weather compensation

Remember when I said that you could save money by running your boiler at lower temperatures? But what happened if it gets really cold outside and you forget to change the setting to higher ones? Or the weather gets warmer and you forget to lower your boiler settings?

This is where weather compensation comes in. It is a little sensor that will cost you around £20-£30. What it does is pretty simple – it gives the external temperature reading to the boiler and the flow temperature gets adjusted automatically so you don’t have to remember to change settings when the temperature outside changes. Weather compensation is probably the cheapest and quickest way to save you biggest amounts of money on your heating bills. This can be used on combi, system and heat only boilers.

3. Do not install S & Y plans – use Domestic Hot Water Priority instead

Weather compensation and low temperature heating creates a problems on antiquated heating systems such as S and Y plans. On those systems the boiler does not know if it is doing heating or hot water. If you put weather compensation on those systems you may struggle to get hot water up to the required temperature. The answer to this problem is stopping installation of S and Y plan systems or conversion of existing systems into what is called a domrstic hot water priority system – DHWP . In those systems the boiler uses weather comp for central heating but it switches to a different output for heating water in the hot water cylinder. Also, hot water takes priority over heating and central heating does not turn on till hot water is satisfied.

If you are getting a new system boiler fittedit may be worth looking for a boiler that can operate in domestic hot water priority mode (DHWP). There is a number of boilers that support DHWP from brands such as Viessman, Intergas, Vaillant and Ideal. The key here is the ability of the boiler to fire at 2 different rates – one for central heating and one for domestic hot water.

4. Stop using on / off controls

A traditional thermostat only acts as a on / off switch and we still see loads of them being fitted. Modern controls offer us what is called Load Compensation. It is usually done through a communication protocol such as Open Therm or eBus on Vaillant.

What those controls do is they send internal temperature to the boiler, compare it to set temperature on the thermostat and choose to fire at different rates depending on the gap between internal temperature and the set point. The bigger the gap between those points the higher the rate the boiler will fire. This gives us extra efficiency and helps to stop the boiler from cycling. The tip here is: when you choose your next boiler make sure that it is compatible with load compensating controls. I choose to use Intergas boilers as they are fully compatible with OT controls.

5. Range rate your boiler, oversize your radiators

Most boilers that I come across in the wild are almost never set up to the system. Those boilers should have been range rated – meaning they should have been adjusted to match the property heat loss at around -2 degrees outside, also know as the worst case scenario. Although there is a requirement to fit efficient condensing boilers, there is no requirement to actually making sure that they operate efficiently once installed.

With heat pumps becoming more popular there is a lot of talk about low temperature heating. We already know that low temperature heating so more efficient, but how is it achieved on condensing gas boilers? It is achieved by calculating the size of your radiators based on lower flow temperatures. Traditionally radiators are tested with the difference between average radiator temperature and room temperature of 50 degrees. But if we want to run our flow around 60 degrees and return at around 40 we will have to design the system with the difference between average radiator temperature and room temperature of around 30 degrees. This means we will have to apply correction factor to the radiators and get much larger radiators.

Good news is – your will be future proofing your property for low temperature appliances such as heat pumps and also saving a bit on your gas bill when using your gas boiler. Saving energy is only one of the bonuses of low temperature heating. Low system temperature also prevents corrosion as the higher the system temperature the the faster the corrosion process. Low temperatures also extend the life of the boiler and your system components by putting less strain on them. I have noticed that expansion vessels for example last much longer on systems that are comissioned correctly and run at lower temperatures.

CONCLUSION

I hope you now start to see the benefits of having an efficient heating system. Now go to your boiler and see what flow setting it is on. If it is at 75 degrees or higher try setting it at 60 or even lower. If you are serious about saving fuel and money – get a weather compensator – it will pay for itself very quickly. If you want extra efficiency – upgrade your radiators to bigger sizes, install load compensating controls and if you have a hot water cylinder and a boiler than can support DHWP – consider converting your S or Y plan into a How Water Priority System.

If you would like to see an efficient installation with DHWP I got a video from one of my installations here. Watch it to see a Hot Water Priority installation:

Hot Water Priority Boiler Installation Video

If you would like a quote for a super efficiecnt central heating & hot water installation you can contact me here: